Upstream Development

Culture. Optimize. Scale.

Cell culture and fermentation development in an execution system. Scale-up predictions from structured data. Process knowledge that survives tech transfer.

The knowledge that died at tech transfer.

The upstream team spent two years optimizing the cell culture process. They knew the subtleties: feed timing that affected glycosylation, temperature shifts that controlled growth, DO setpoints that balanced titer against product quality. They documented everything—in their way. Notebooks, spreadsheets, presentations.

Tech transfer came. Manufacturing received a process description, a batch record, and operating ranges. The subtleties—the tribal knowledge that made the process work—were buried in development data that nobody at the manufacturing site could navigate. The first GMP batches struggled. Parameters were "in range" but results were inconsistent. The knowledge was there, somewhere, but it wasn't accessible.

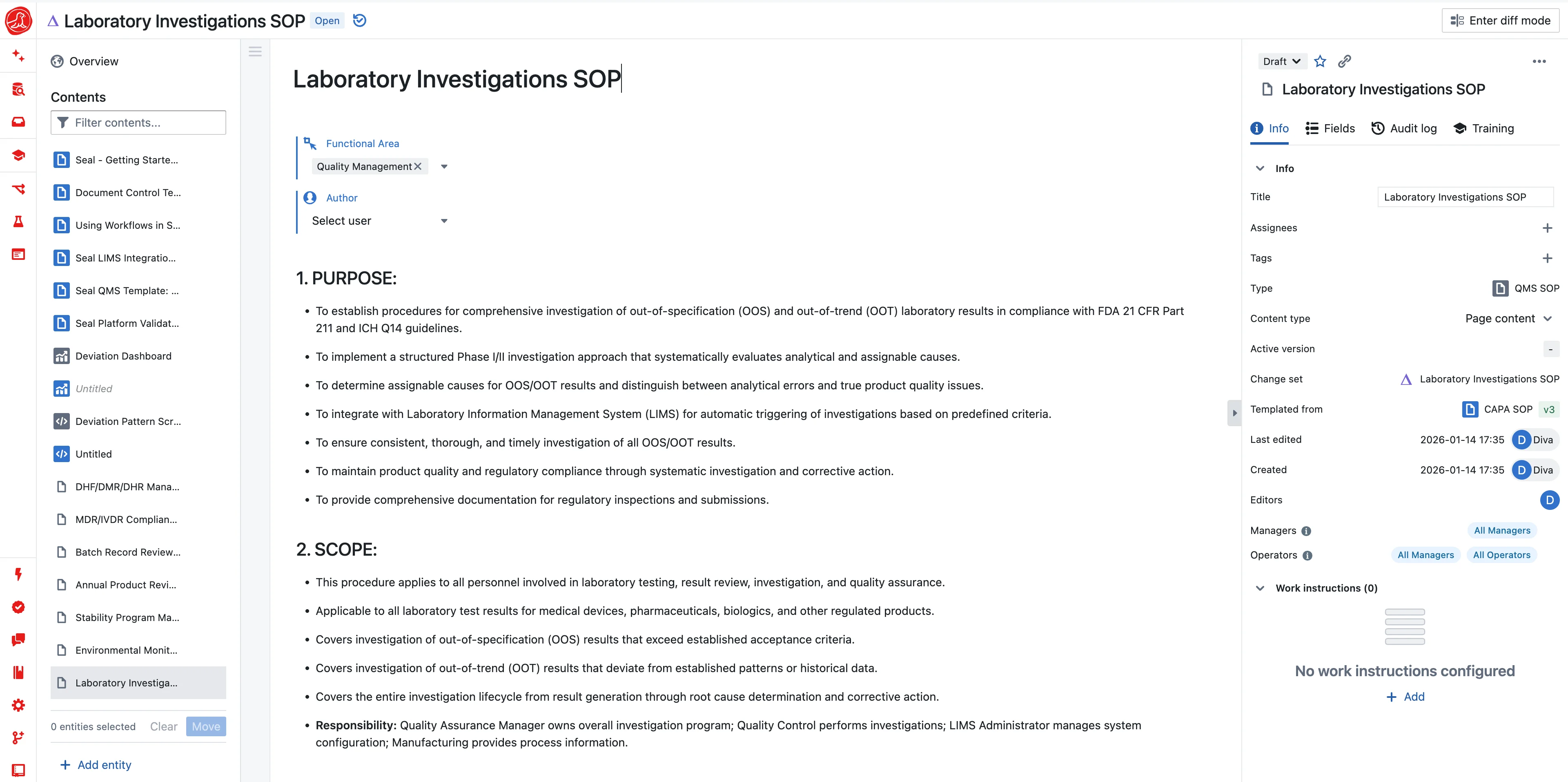

Cell culture in an execution system

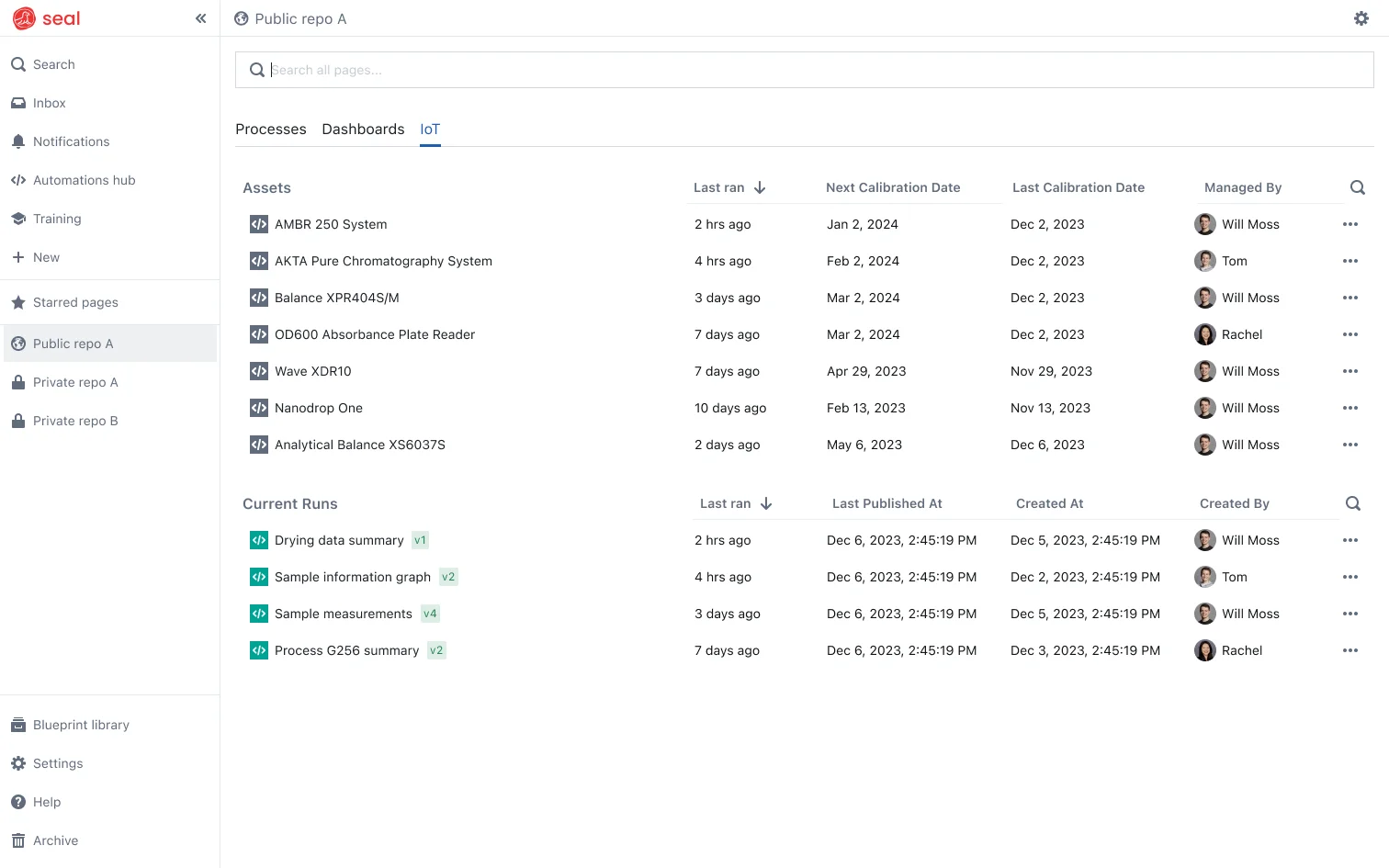

Most cell culture development happens in documentation systems. Scientists run experiments and document them, but the parameters that drove results—the actual inputs, the timing, the feeds—are often reconstructed from memory when it's time to write the report. Seal is an execution system for cell culture where scientists define their runs as structured workflows. As the run progresses, parameters capture automatically from equipment, feed additions record as they happen, and samples link to analytical results. The run isn't documented after the fact—it's recorded as it executes.

Media development is iterative. Component concentrations change, feed strategies evolve. Seal versions media formulations automatically, so when you modify a component concentration that's a new version, and when you run a bioreactor with that media the link is explicit. When results differ between runs, you can see exactly what was different—not "we changed the feed" but "Feed 3 glucose concentration was 400g/L in run 12, 450g/L in run 15." Feed strategies work the same way: versioned protocols linked to runs, enabling apples-to-apples comparison between different approaches.

Scale-up, clone selection, and process modes

Scale-up is the existential risk of upstream development. The process that works at 2L doesn't automatically work at 200L or 2000L. Seal captures scale relationships as structured data—when you run at multiple scales, the data is already aligned by process. Scale correlations build from actual data: this mixing time at 2L corresponds to this kLa at 200L corresponds to this impeller speed at 2000L. When you plan scale-up, you're querying your actual experience, not hoping your spreadsheet is current.

Clone selection determines program success. The clone you choose defines your productivity, your product quality profile, your manufacturing flexibility. Seal structures clone selection as a defined workflow where the attributes that matter—growth rate, specific productivity, product quality, genetic stability—are configured as selection criteria. As you screen clones, data populates against these criteria. Selection is based on structured comparison of actual data, not whoever compiled the best PowerPoint.

Perfusion culture presents unique challenges: continuous media exchange, cell retention, steady-state operation over weeks. Most systems treat perfusion as a variation of fed-batch, missing the continuous nature. Seal models perfusion as continuous operation with media exchange rates, bleed rates, and cell density trends captured as time-series data. Steady-state identification is data-driven, and the development system understands what perfusion means.

Cell line, seed train, and product quality

Your cell line is your product's foundation. Seal maintains cell lineage as connected data: master cell bank links to characterization studies, working cell banks link to the master, production cultures link to the working bank that seeded them. When FDA asks about your cell substrate, the lineage is queryable—not reconstructed from archives.

The production bioreactor gets the attention, but the seed train—N-3, N-2, N-1 stages—determines what the production reactor receives. Seal models the full expansion from vial to production with seed train stages linked to production runs. When production results vary, you can trace back through the seed train. When you optimize seed stages, you see the impact on production.

Cell culture conditions affect product quality. Glycosylation profiles shift with dissolved oxygen, charge variants change with pH, aggregation correlates with viability at harvest. Seal links process execution to product quality—when you sample a bioreactor, the sample links to run conditions at that moment. When quality testing completes, results connect to process data. Building understanding of process-quality relationships happens from integrated data, not reconciled exports.

Process transfer and AI insights

When upstream processes transfer to manufacturing, the batch record is usually written fresh by someone interpreting development data. Seal eliminates this translation by keeping development and manufacturing on the same platform. The upstream process you developed—the actual workflow, parameters, and controls—promotes to manufacturing. What tightens is enforcement; what preserves is understanding. The manufacturing team doesn't just know what to do. They can see why.

Upstream doesn't exist in isolation. What happens in the bioreactor affects purification—harvest timing affects product quality, cell culture conditions influence downstream yield. Seal connects upstream to downstream so the harvest from a bioreactor run links to the purification runs that processed it. When you optimize end-to-end, you're working with connected data, not reconciling exports.

Upstream processes generate vast amounts of data. Seal applies AI to this data—natural language queries let you ask "show me runs with titer above 5 g/L and viable cell density above 20M/mL at harvest" and get immediate answers. Pattern recognition identifies relationships you might not have looked for. Your development archive contains years of runs, data in historians and spreadsheets representing millions of dollars of investment. AI-assisted extraction pulls parameters and results from legacy sources, so when you develop a new process you're building on everything you've learned.

Capabilities