503B Compounding Facility

Compound. Comply. Scale.

The 2012 outbreak killed 64 people. A decade later, most 503B facilities still run on paper batch records and Excel EM logs. Pharmaceutical manufacturing standards with retail pharmacy tools don't work.

The contamination nobody saw coming

The FDA investigator arrived on a Tuesday. By Thursday, the facility was shut down. Sixty-three patients had received contaminated injections. The fungal contamination traced back to an environmental monitoring failure that had been documented—but buried in spreadsheets nobody reviewed.

The 2012 NECC meningitis outbreak killed 64 people and changed compounding pharmacy regulation forever. Congress created the 503B designation: outsourcing facilities that compound without patient-specific prescriptions, subject to CGMP requirements and FDA oversight. The regulatory burden increased dramatically. The systems most facilities used didn't.

A decade later, most 503B facilities still run on paper batch records, Excel environmental monitoring logs, and Word document SOPs. They're trying to meet pharmaceutical manufacturing standards with retail pharmacy tools. It doesn't work. The FDA knows it. Their inspection findings prove it.

You're a manufacturer now

The moment you registered as a 503B outsourcing facility, you became a pharmaceutical manufacturer in the eyes of the FDA. Not a pharmacy that compounds. A manufacturer that produces drug products.

This distinction matters because CGMP (Current Good Manufacturing Practice) requirements apply. You need:

- Batch production records that document every step of compounding

- Environmental monitoring programs with trending and alert limits

- Equipment qualification and ongoing calibration

- Personnel training with documentation and competency verification

- Quality systems including deviation management, CAPA, and change control

- Stability programs supporting your beyond-use dating claims

Most 503B facilities bolt these requirements onto existing pharmacy workflows. The result: parallel systems that don't talk to each other, manual data compilation for every FDA inspection, and gaps that become warning letters.

The environmental monitoring problem

Sterile compounding lives or dies on environmental control. Your ISO 5 areas, ISO 7 buffer rooms, and ISO 8 ante rooms need continuous monitoring. Viable and non-viable particle counts. Temperature and humidity. Pressure differentials. Surface sampling. Personnel monitoring.

Most facilities collect this data. Few actually use it. The viable counts go into a spreadsheet. Someone reviews them weekly—maybe. Trends that would reveal a developing problem get lost in rows of numbers. By the time a count exceeds the action limit, contamination has already occurred.

Seal treats environmental monitoring as a continuous program, not a data collection exercise:

Scheduled sampling: The system generates sampling schedules based on your monitoring plan. Technicians see what's due today, what's overdue, and what's coming. Nothing falls through the cracks.

Real-time trending: As results enter the system, they plot on trend charts automatically. You see patterns emerging over weeks and months—not just individual data points.

Alert and action limits: Define limits per location and sample type. When a result approaches the alert limit, the system notifies. When it exceeds the action limit, investigation workflows trigger automatically.

Excursion management: When environmental control fails, you need to assess impact immediately. Which products were in the affected area? What was the duration? Seal connects environmental data to batch records so you can answer these questions in minutes, not days.

Beyond-use dating that you can defend

Every sterile compounded product needs a beyond-use date. USP <797> provides the framework. But "the framework" and "defensible documentation" are different things.

When an FDA investigator asks how you determined your BUD for a specific product, what do you show them? A reference to USP <797> isn't enough. They want to see stability data, container closure integrity testing, and documented rationale for your dating claims.

Seal manages BUD determination as a structured process:

Dating categories: Define your standard BUDs based on USP <797> categories—CSPs prepared under various conditions with corresponding dating limits.

Extended dating justification: When you claim dating beyond default USP limits, document the supporting data. Link to stability studies. Reference container closure testing. The rationale lives with the product definition, not in a binder somewhere.

Batch record integration: When an operator compounds a batch, the system calculates the BUD automatically based on the product definition and preparation conditions. No manual calculation. No transcription errors.

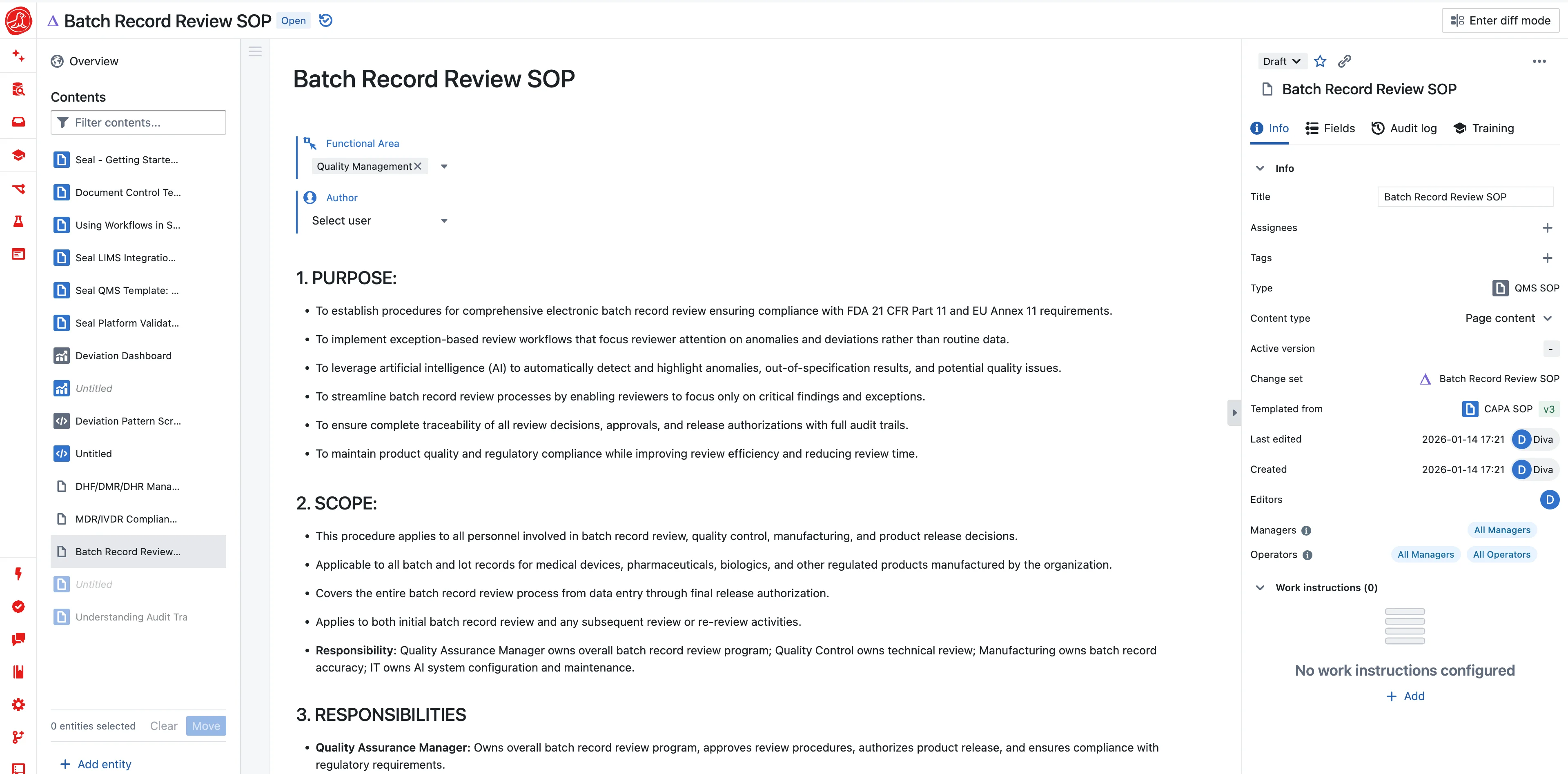

Batch records that prove compliance

Paper batch records are liability documents. Every blank space, every correction, every illegible entry becomes a question during an FDA inspection. "Why is this field empty?" "Who made this correction and why?" "What does this say?"

Electronic batch records in Seal eliminate these questions:

Guided execution: Operators follow step-by-step instructions. Required fields must be completed before proceeding. The system enforces the sequence you defined.

Component verification: Scan barcodes to verify correct ingredients, correct lot, correct quantity. Wrong component? The system blocks it. Expired lot? Blocked. The errors that contaminate batches become physically impossible.

Real-time documentation: Data captures as work happens. No end-of-shift transcription from notes to records. No "I'll fill that in later." The batch record builds itself as the batch is made.

Automatic calculations: Yields, concentrations, dilution factors—calculated by the system, not by technicians doing math under time pressure. The calculation that's wrong on paper is right in Seal because the formula is validated once and applied consistently.

Electronic signatures: Every critical step signed electronically with Part 11 compliant signatures. Who did what, when, with what meaning. No signature hunting at the end of the shift.

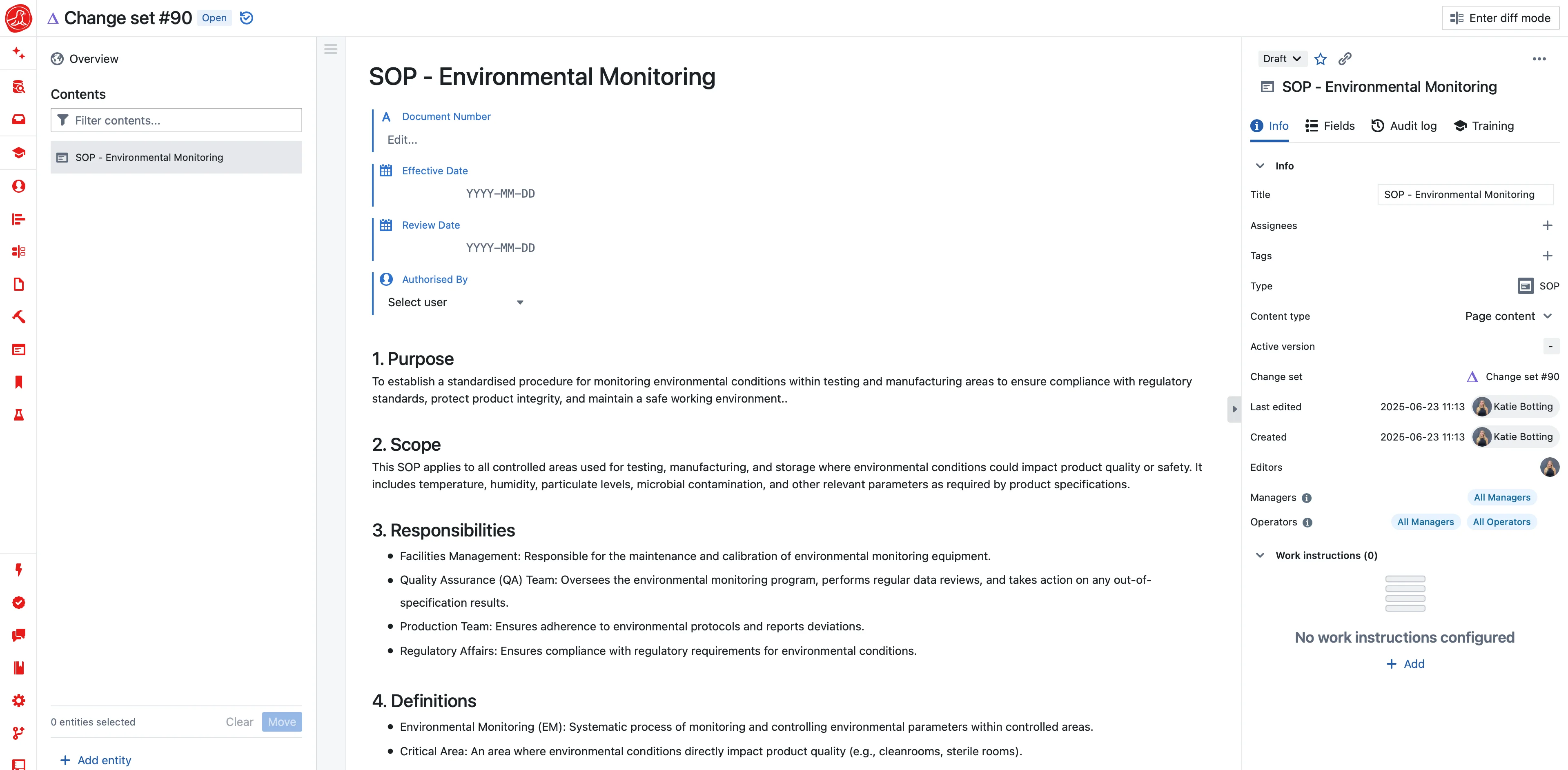

Master formulas that don't drift

You developed your formulations carefully. You validated them. You documented them. Then someone made a "small adjustment" that wasn't captured anywhere, and now your actual process doesn't match your documentation.

Seal maintains master formulas as controlled documents:

Version control: Every formula change goes through change control. Version 1.0 becomes 1.1 with documented rationale, approval, and effective date.

Batch record generation: When you start a batch, the system generates the batch record from the current master formula. The record reflects exactly what's approved—not someone's memory of what should happen.

Parameter enforcement: Critical parameters have limits. The formula says pH 7.0 ± 0.2. If the measured pH is 7.3, the system flags it as out of specification before the batch proceeds.

The USP chapter maze

USP <797> for sterile compounding. USP <800> for hazardous drugs. USP <795> for non-sterile. USP <71> for sterility testing. USP <85> for endotoxin. The requirements layer on top of each other, and keeping track of which apply to which products is a compliance challenge in itself.

Seal maps USP requirements to your products and processes:

Product classification: Define whether each product falls under <797>, <800>, or both. The system applies appropriate requirements automatically.

Testing requirements: Sterility testing per <71>, endotoxin testing per <85>—linked to products that require them. The batch doesn't release until required testing is complete and passing.

Documentation alignment: When an investigator asks about your <797> compliance for a specific product, pull the complete documentation package: formula, batch records, environmental data, testing results, BUD justification. Everything linked, everything accessible.

Hazardous drug compounding under USP 800

Many 503B facilities compound hazardous drugs—chemotherapy agents, hormones, antineoplastics. USP <800> adds requirements on top of <797>: negative pressure rooms, closed-system transfer devices, enhanced PPE, surface decontamination, and medical surveillance.

The challenge is maintaining two parallel sets of controls and proving you're doing it correctly. HD compounding in the wrong room. Non-HD products contaminated by residue. Personnel exposure because controls weren't followed. These failures happen when systems don't enforce the separation.

Seal manages hazardous drug compounding with explicit controls:

HD classification: Products are flagged as hazardous drugs at the formula level. The system knows which products require <800> controls.

Room assignment: HD products must be compounded in designated negative-pressure rooms. The system blocks HD batches from starting in non-HD areas.

PPE verification: Before starting an HD batch, operators confirm required PPE: chemotherapy gowns, double gloves, eye protection. The confirmation is part of the batch record.

Surface decontamination: Cleaning procedures for HD rooms differ from standard cleanrooms. The system assigns HD-specific cleaning protocols and tracks completion.

Spill management: If a spill occurs, the system guides the response: containment, cleanup procedure, incident documentation. The spill record links to the batch and affected personnel.

Medical surveillance: Track which personnel work with hazardous drugs and when their medical surveillance is due. Ensure compliance with occupational health requirements.

Personnel qualification tracking

Compounding sterile products requires trained, qualified personnel. Media fill testing. Garbing qualification. Aseptic technique assessment. These aren't one-time events—they require periodic requalification.

Seal tracks personnel qualification:

Qualification status: See at a glance who's qualified for which activities. Whose media fill is current. Who needs requalification next month.

Work authorization: The system can block unqualified personnel from executing controlled steps. Operator not media-fill qualified? They can't sign off on aseptic compounding steps.

Training curricula: Define what training is required for each role. New hires see their complete training path. Managers see completion status across their teams.

Cleaning and sanitization

ISO classified areas require documented cleaning and sanitization programs. Rotation of sanitizing agents. Sporicidal treatments. Surface monitoring to verify effectiveness.

Seal manages cleaning as part of your environmental control program:

Cleaning schedules: Daily, weekly, monthly tasks assigned to personnel with completion tracking.

Agent rotation: Define your sanitization agent rotation. The system prompts for the correct agent based on the schedule.

Effectiveness verification: Link surface sampling results to cleaning events. Did sanitization work? The data answers the question.

Filling the gaps in drug supply

503B facilities exist because the traditional pharmaceutical supply chain fails. Drug shortages. Discontinued products. Doses that manufacturers won't make because the market is too small. You fill those gaps—but only if hospitals trust you to do it right.

Hospital pharmacy directors and health system supply chain managers are increasingly sophisticated buyers. They've seen the headlines. They know the risks. Before they'll put your products in their patients, they want to see your quality systems.

Customer audits: Health systems audit their 503B suppliers. With Seal, you're ready. Pull environmental trends, batch records, deviation history, CAPA effectiveness—everything they want to see, organized and accessible.

Quality agreements: Many customers require quality agreements specifying your obligations. Track these agreements, link them to customers, and demonstrate compliance with the commitments you've made.

Product specifications: Different customers may have different requirements for the same product. Manage customer-specific specifications and ensure the right specs apply to the right orders.

Lot traceability: When a customer asks "which lots did we receive in Q3?", answer in seconds. When you need to notify customers about a quality issue, know exactly who received which lots.

The 503B facilities winning business aren't just the ones with the lowest prices. They're the ones who can demonstrate quality systems that sophisticated buyers trust.

When FDA arrives

The question isn't whether FDA will inspect—it's whether you'll be ready. 503B facilities receive regular inspections, and the bar is pharmaceutical manufacturing, not retail pharmacy.

Seal transforms inspection readiness from a scramble into a non-event:

Batch record retrieval: Inspector wants to see batch 2024-0847? Pull it in seconds. Complete record with all signatures, all data, all deviations.

Environmental trending: Show continuous monitoring data with trend analysis. Demonstrate that you're not just collecting data—you're using it.

Training documentation: Prove personnel are qualified. Show training records, media fill results, competency assessments.

CAPA effectiveness: When they ask about your corrective actions, show that you verify effectiveness—not just that you closed the CAPA.

The facilities that struggle during inspections are the ones compiling documentation in real time. The facilities that succeed have systems where the documentation already exists, already organized, already accessible.

The cost of not changing

You can keep running on paper and spreadsheets. Many 503B facilities do. But consider the costs:

Warning letters that require extensive remediation and shake customer confidence 483 observations that accumulate into consent decrees Product recalls when contamination isn't caught in time Lost customers who require electronic quality systems from their suppliers Staff burnout from manual documentation and inspection preparation

The investment in proper systems pays for itself the first time you avoid a serious compliance event. More importantly, it lets you focus on what matters: compounding quality products that help patients who need medications the traditional supply chain can't provide.

Capabilities