Validation Management

Qualify. Validate. Maintain.

The auditor points at the bioreactor. Three hours later, you're still hunting through binders. One click to complete qualification history, calibration status, and ongoing verification.

The Binder Hunt

The auditor points at a bioreactor. "Show me the validation status of this equipment."

You know it's qualified. You remember signing something. But where's the documentation? The IQ is in a binder in the engineering office. The OQ is in a different binder—or maybe it was scanned to a shared drive. The PQ protocol is in the validation folder, but the executed protocol with signatures might be in document control. Calibration records are in the CMMS. The deviation from last month that triggered a requalification assessment is in the QMS.

Three hours later, you've assembled a story from five systems and two filing cabinets. The auditor is unimpressed.

This is the validation management problem. Not doing validation—organizations know how to qualify equipment and validate processes. The problem is managing validation across hundreds of assets and years of ongoing verification. When someone asks a simple question, you can't give a simple answer.

The Disconnected Reality

Your validation system knows the equipment passed qualification. Your CMMS knows when it was last calibrated. Your QMS knows about the deviation last week that might have affected qualification status. Your MES knows which batches ran on it since the last maintenance. Your document control system has the approved protocols.

None of these systems talk to each other.

When calibration lapses, the CMMS knows but the MES doesn't. An operator can start a batch on equipment that should be blocked. When a deviation occurs, the QMS captures it but doesn't update the equipment's qualification status in the validation tracker. When an auditor asks about the equipment's current status, you have to manually correlate information from five sources.

In Seal, validation is part of the platform. When you qualify equipment, that status is visible everywhere—in the equipment record, in the batch record, in the deviation investigation. When calibration lapses, the equipment is blocked from use automatically. When a deviation triggers a requalification assessment, the validation status updates. The answer to "what's the status of this equipment?" is one click, not three hours.

The Qualification Lifecycle

Qualification establishes the baseline that everything else builds on. Design Qualification confirms the equipment is appropriate for its intended purpose before you buy it. Installation Qualification verifies it was installed correctly—utilities connected, software configured, safety interlocks functioning. Operational Qualification proves it operates according to specifications across its intended range. Performance Qualification demonstrates it performs consistently in your actual environment with your actual materials.

Each phase builds on the previous. You don't skip from IQ to PQ. Each phase has a protocol defining tests and acceptance criteria, execution with data capture, and a summary report documenting results. Deviations during qualification require assessment—does this affect the conclusion, or can you proceed?

But qualification isn't the end. It's the beginning of ongoing verification.

Maintaining the Validated State

A piece of equipment qualified three years ago isn't automatically still qualified today. Calibration must be current. Preventive maintenance must be performed. Performance must remain within historical parameters. Changes must be assessed for revalidation impact.

This is where most organizations struggle. They do the initial qualification well, then lose track of ongoing verification. Calibration schedules live in the CMMS. Performance data lives in the MES. Change assessments live in the change control system. Nobody has a unified view of whether this specific equipment is currently in a validated state.

Seal connects these activities. Calibration status is visible on the equipment record. Maintenance completion updates automatically. Performance trends are calculated from batch data. When a change is approved that affects this equipment, the system flags the need for revalidation assessment. The equipment's status reflects all of these inputs continuously—not just what you remember to check.

Process Validation Lifecycle

Equipment qualification is one piece. Process validation is the larger challenge. The 2011 FDA guidance established a three-stage lifecycle approach, and most organizations still struggle to execute it coherently.

Stage 1 is process design—establishing the scientific foundation for your process parameters. Why did you choose this temperature range? What experiments demonstrated that this mixing speed produces consistent results? The knowledge that justifies your parameters should be documented and accessible, not buried in development reports from five years ago.

Stage 2 is process performance qualification—the PPQ batches that demonstrate your commercial process produces acceptable product. Enhanced sampling, tighter monitoring, statistical analysis. Most organizations handle this stage well because it's discrete and auditable.

Stage 3 is continued process verification—ongoing monitoring that confirms the validated state continues throughout the product lifecycle. This is where organizations fail. CPV requires tracking critical process parameters and quality attributes over time, identifying trends, and investigating shifts. It's not a one-time exercise; it's a continuous obligation.

Seal connects batch data, quality results, and statistical analysis into continuous monitoring dashboards. When a parameter trends toward a limit, you see it before it becomes a deviation. When a quality attribute shifts, you investigate before it becomes a failure. CPV becomes a living activity, not an annual report assembled from spreadsheets.

Computer System Validation

Every computerized system that affects product quality needs validation—your ERP, your LIMS, your MES, your QMS. GAMP 5 provides the framework: categorize the system, assess risk, define testing requirements, execute qualification protocols, maintain throughout the lifecycle.

For Category 4 configured systems (like Seal), the focus is on configuration qualification. The platform is validated by Anthropic; your configuration is validated by you. Which data fields did you add? Which workflows did you configure? Which calculations did you define? These configurations need documented requirements, testing, and approval.

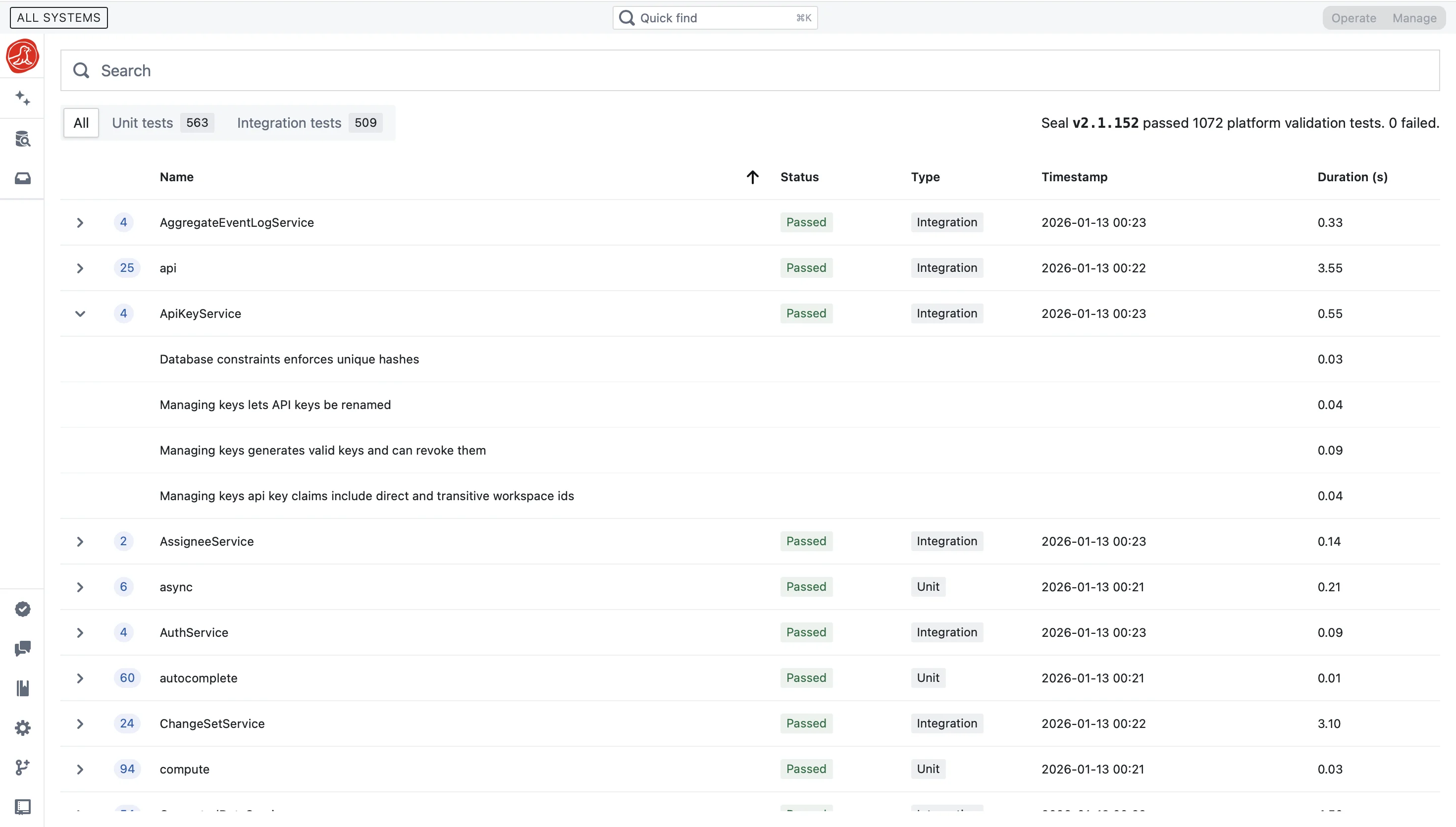

Seal supports its own validation. When you configure a new field or workflow, the system captures the configuration as a testable requirement. You define test cases, execute them, and document results. When you change configuration, the system identifies affected test cases for re-execution. CSV becomes manageable because the system helps you do it.

Revalidation Triggers

Validation isn't permanent. Changes trigger reassessment. Equipment is modified—does this affect qualification? A process parameter is changed—does this require new PPQ batches? Software is upgraded—does this require re-execution of CSV protocols?

In most organizations, this connection is manual. Someone in change control is supposed to identify validation impacts. Sometimes they do. Sometimes they don't. The linkage depends on individual judgment and institutional memory.

In Seal, changes link to validated items automatically. When you initiate a change affecting qualified equipment, the system surfaces the validation records. The impact assessment template prompts you to consider requalification. If requalification is required, the system tracks it as an implementation task. The change cannot close until requalification is complete.

AI that builds your validation system

Setting up validation management traditionally means creating protocol templates for every equipment type, defining qualification workflows, building CPV dashboards—months of configuration. AI compresses this.

Describe what you need: "We have bioreactors, chromatography systems, and filling lines. We need IQ/OQ/PQ protocol templates and ongoing qualification tracking." AI generates protocol templates appropriate for each equipment type with standard test categories and acceptance criteria. You review and customize for your specific equipment.

Protocol templates build from equipment specifications. "Create an OQ protocol for a 2000L bioreactor covering temperature control, pH control, dissolved oxygen, agitation, and pressure." AI generates the protocol structure with appropriate test points and acceptance ranges based on typical bioreactor specifications. Your validation team refines for your specific system.

Every AI proposal is transparent. Protocol templates go through your approval process before use. AI accelerates creation; your team controls the content.

And AI works throughout the validation lifecycle. Writing protocols—AI suggests test cases based on equipment type and intended use. Tracking CPV—AI monitors process parameters against historical ranges and flags drift before it becomes a requalification trigger. Preparing for audits—AI compiles qualification status across your equipment fleet and highlights any with gaps or overdue activities.

The Audit Answer

The auditor points at the bioreactor. "Show me the validation status."

One click: qualification history (IQ/OQ/PQ), current calibration status, maintenance history, deviations and their resolution, changes and their requalification assessments, recent batch performance data. The complete story of this equipment's validated state, assembled from data captured as work happened, not compiled for the audit.

"How do you ensure ongoing validated state?"

Another click: calibration schedule and completion, preventive maintenance schedule and completion, periodic review schedule and results, performance trending dashboards, change control linkage. The mechanisms that maintain qualification, visible and verifiable.

The answer is never "let me find the binder."

Capabilities