Supplier Quality

Qualify. Monitor. Improve.

The supplier nobody was watching. 12 lots rejected. 3 SCARs still open. Acceptance dropped from 94% to 87%. The data was there—nobody connected it into a picture.

The supplier nobody was watching.

ABC Materials had been your API supplier for three years. Qualification was thorough—audited their facility, reviewed their quality system, tested initial lots. Everything passed.

Over the next three years: 12 lots rejected at incoming inspection. 3 SCARs issued, 2 still open from last year. 4 audit observations, 2 unresolved. Quality trending downward—94% acceptance rate two years ago, 87% last quarter.

The data was all there. Nobody had connected it into a picture.

Then Lot 2024-103 failed release testing. The investigation traced the failure to the API. This wasn't a sudden problem—it was the latest data point in a three-year decline.

The supplier lifecycle

Identification → Qualification → Onboarding → Monitoring → Development → Exit.

Most organizations handle the first three phases reasonably well. They fail at monitoring because they lack the data to understand supplier performance over time.

Incoming inspection

Reduced inspection for suppliers with strong track records. Tightened inspection when problems emerge. Skip lot for highly reliable suppliers and non-critical materials.

When incoming inspection finds a problem, the system can automatically tighten inspection for that supplier.

CoA verification

Suppliers provide CoAs claiming their material meets specifications. Seal compares CoA data to your specifications automatically. If the CoA shows a result outside your acceptance criteria, the system flags it—even if the supplier considers it acceptable.

SCARs

When supplier quality fails: document the issue, notify the supplier, evaluate their response, verify effectiveness.

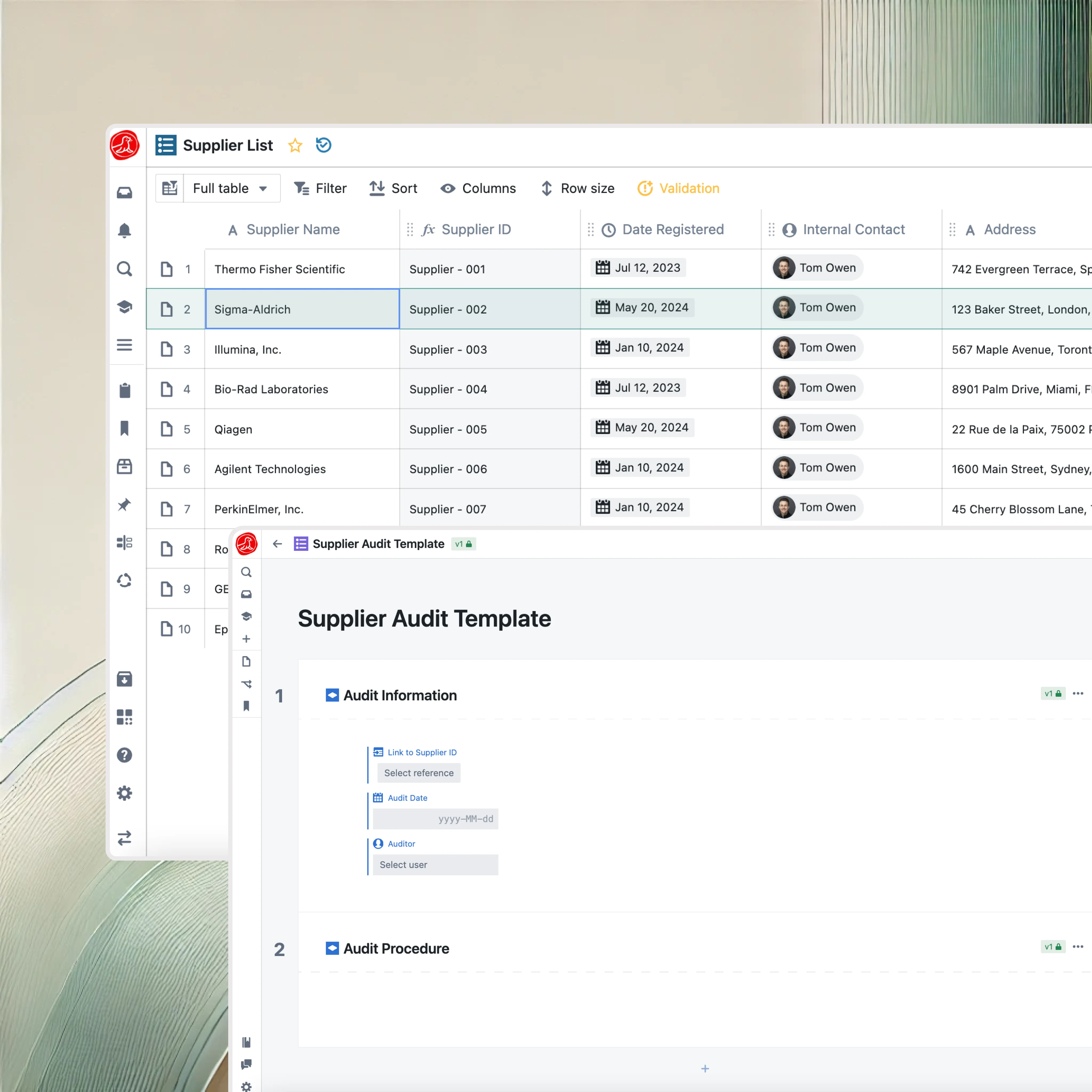

Seal tracks SCARs from initiation through closure, with escalation when suppliers don't respond. You can see which suppliers have open SCARs, which are overdue, which have recurring issues.

Performance scorecards

Computed automatically from actual transaction data: on-time delivery rate, incoming inspection pass rate, SCAR response time. A supplier trending downward on quality triggers review. A supplier with strong performance qualifies for reduced inspection.

Capabilities