Weigh & Dispense

Scan. Weigh. Verify.

The $400,000 mistake takes three seconds. Barcode verification blocks wrong materials—not warns, blocks. Balance integration eliminates transcription entirely.

The $400,000 mistake that took three seconds to make.

Building 3, Tuesday morning, 6:47 AM. An operator reaches for Sodium Chloride USP to dispense into a buffer formulation. Two containers sit side by side on the shelf—both white powder, both labeled "Sodium Chloride," both from the same supplier. He grabs the one on the left. It's the wrong grade.

The batch proceeds. Downstream processing completes. Fill-finish runs overnight. By Wednesday afternoon, 847 vials of a biologic product sit in quarantine. QC results come back Thursday: out of specification. The investigation traces back to the wrong salt grade—a container that should have been in a different warehouse zone, a label that looked right at a glance, a split-second decision made before dawn.

Total cost: $400,000 in destroyed product, 5 days of investigation, 2 weeks of schedule disruption, and a CAPA that will require retraining every operator in the facility. All because someone grabbed the wrong container.

The six failure points in every manual dispense

Every time an operator dispenses material by hand, they navigate six opportunities for error. They read the label visually—and similar labels look identical at 6 AM. They check the lot manually—and expiry dates in small print get missed. They calculate the quantity by hand—and 4.532 becomes 4.352 when you're working from memory. They read the balance display—and transposition happens. They write the weight on paper—and digits get swapped. And finally, they hope a reviewer catches any mistakes—knowing that reviewers check hundreds of entries and miss things.

This isn't about bad operators. It's about bad architecture. You've built a system where human vigilance is the only barrier between a momentary lapse and a destroyed batch. The more batches you run, the more certain you are to experience a failure.

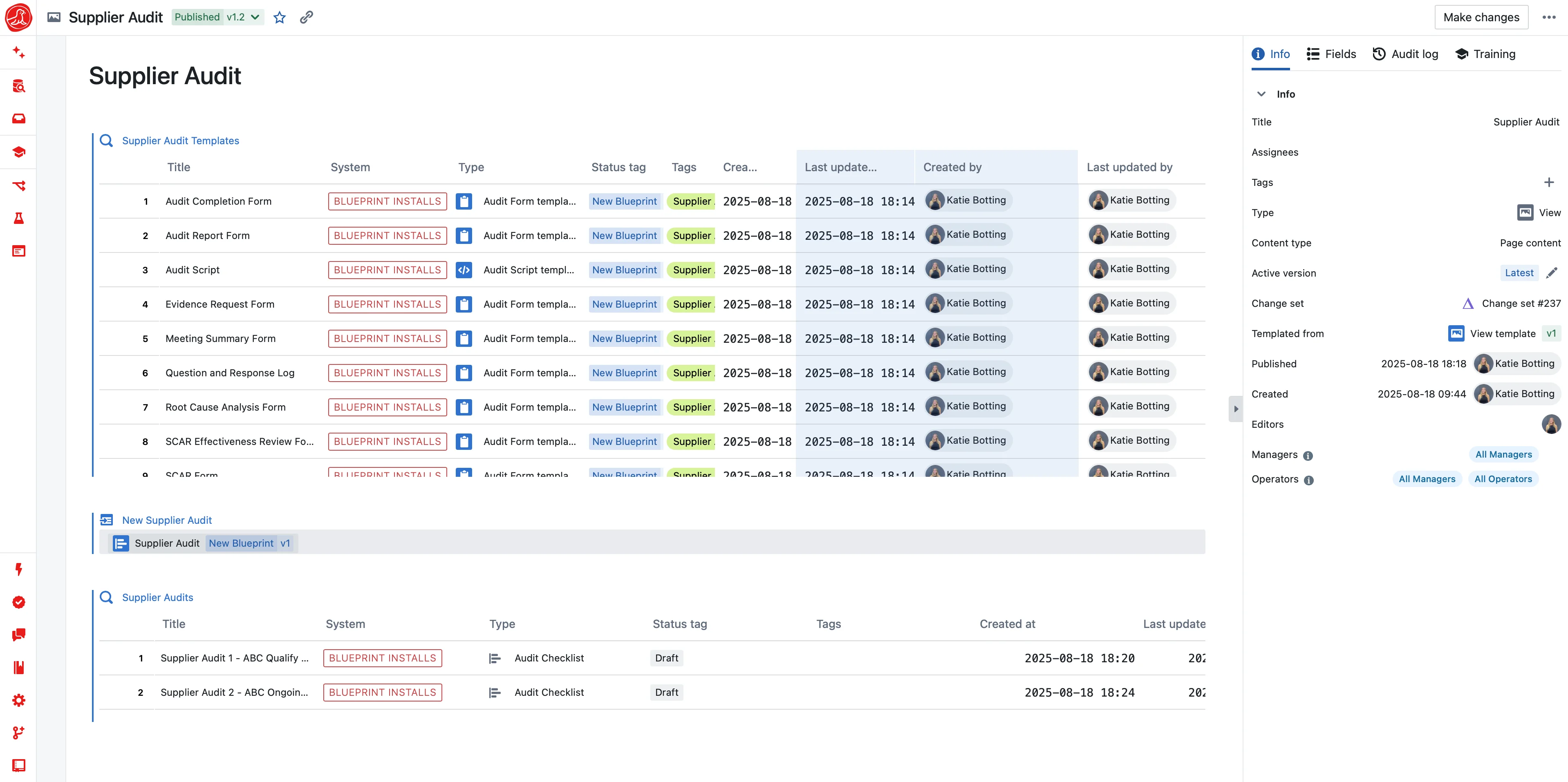

Barcode verification: blocked, not warned

Seal's weigh and dispense module doesn't warn operators about wrong materials. It blocks them.

When an operator scans a material barcode, the system checks everything: Is this the correct material for this step? Is this specific lot released for use? Is the lot expired or approaching expiry? Is it quarantined pending investigation? Is it the correct grade for this product? Are materials being added in the required sequence?

If anything fails, the workflow stops. Not a dialog box that can be clicked through. Not a warning that gets dismissed because operators see it a hundred times a day. A hard stop that requires scanning the correct material before the process continues.

The operator who grabbed the wrong sodium chloride at 6:47 AM would have scanned the barcode, seen "Material does not match. Expected: Sodium Chloride USP (Cat# SC-USP-500). Scanned: Sodium Chloride ACS (Cat# SC-ACS-500)," and returned the container to the shelf. Three seconds of scanning instead of $400,000 in losses.

Weights that capture themselves

The transcription problem disappears when balances connect directly to the system. When an operator places material on the scale, the weight flows into the batch record automatically. The reading that appears on the balance display is the reading that appears in the batch record—not a number someone read, remembered, and typed.

Real-time guidance replaces mental math. The display shows target weight, current weight, and remaining amount: "Target: 4.532 kg | Current: 3.285 kg | Add: 1.247 kg." Operators follow the numbers instead of calculating in their heads. When batch sizes change, the system recalculates every material quantity automatically. The operator always sees the correct target for the batch they're actually making.

For high-precision dispenses—active pharmaceutical ingredients, potent compounds, anything where milligrams matter—the system enforces tighter tolerances and can require verification at specific checkpoints. The same workflow that handles bulk excipients handles microgram-level API dispensing.

Tolerances that guide instead of punish

Traditional dispensing creates anxiety around tolerances. Operators overshoot or undershoot, panic, make adjustments, and sometimes create deviations trying to hit an exact number. The system should help them succeed, not catch them failing.

Seal shows real-time tolerance status as material is added. Green means within range. Yellow means approaching limits. Red means out of tolerance. Operators see where they are relative to the target and can adjust—add a bit more, remove the excess—before they've committed to a number outside specification.

When the final weight genuinely can't be brought into tolerance, the system captures the exception with full context. What was the target? What was actually dispensed? What corrections were attempted? The deviation documentation writes itself, with everything an investigator needs. No one has to reconstruct what happened from memory three days later.

Complex formulations, simple execution

Some batches require dozens of materials added in precise sequences. Buffer A before Buffer B. Excipients before API. Pre-mix before final formulation. Traditional paper-based dispensing relies on operators following instructions correctly. Seal enforces the sequence structurally.

Materials appear in order. Operators can't skip ahead. If step 7 requires completing step 6, step 7 doesn't unlock until step 6 is verified complete. When formulations require splitting materials across multiple containers, the system tracks cumulative weight across dispenses. Verification points can require QC or supervisor sign-off at critical stages.

Container management is built in. Scan the container barcode, capture the tare weight, and the system calculates net material weight automatically. For standard containers with known tare weights, stored values eliminate redundant weighing. The result is complete genealogy from dispense through processing—you always know which container holds which material for which batch.

Inventory that updates itself

Dispensing doesn't exist in isolation. When an operator needs material, they need to know what's available: which lots, what quantities, what status. Traditional systems require checking one system for inventory, another for lot status, and a third for the batch record.

Seal shows available lots with their quantities and status in the dispensing workflow itself. Operators select which lot to use based on FEFO rules or specific requirements. When material is dispensed, inventory updates automatically—no separate transaction, no double entry, no reconciliation at month end.

The batch record captures exactly which lots of which materials were used, providing forward and backward traceability. Click any finished product to see every raw material lot that went into it. Click any raw material lot to see every batch it was used in. When a supplier issues a recall, you know in seconds which batches are affected.

Potent compounds require more

When you're dispensing milligrams of a highly potent API, the stakes multiply. A small error becomes a large percentage deviation. Exposure risks require containment. Regulatory scrutiny increases.

Seal handles potent compounds with configurable rigor based on OEL (Occupational Exposure Limit) bands:

Containment enforcement: The system knows which materials require isolators, glove boxes, or other containment. It won't allow dispensing to proceed until the operator confirms containment is in place. The balance must be in the designated containment area.

Tighter tolerances: Potent compounds often require ±0.5% or tighter. The tolerance guidance adjusts accordingly. What would be acceptable variance for an excipient triggers alerts for an API.

Double verification: For high-potency materials, a second person must verify the weight. Both the operator and witness see the balance reading. Both sign off electronically. The batch record captures both signatures with timestamps.

Analytical balance requirements: Microgram precision requires analytical balances with appropriate resolution. Seal tracks which balances are qualified for which precision levels and blocks use of inadequate equipment.

The same workflow that handles bulk excipients handles microgram API dispensing—same interface, different controls enforced based on material classification.

Reconciliation closes the loop

Dispensing isn't complete when material enters the batch. You need to account for what remains. Did you dispense what you expected to dispense? Does the inventory balance?

Seal tracks material reconciliation automatically:

Theoretical vs actual: The system calculates expected usage based on the batch formula. After dispensing, it compares actual dispensed quantities. Discrepancies trigger investigation—did material spill? Was more used than expected? Is there a yield problem?

Container accountability: When you open a container, you know how much was in it. When you close it, you know how much remains. The delta should equal what you dispensed. If it doesn't, the system flags the discrepancy before you move on.

Yield calculations: Dispensing data feeds directly into batch yield calculations. No manual compilation at batch close. The system knows exactly how much raw material went in and can compare to how much product came out.

Label printing for dispensed materials

Once material is dispensed into a container, that container needs identification. What batch is this for? What material? What quantity? When was it dispensed?

Seal generates container labels automatically. When dispensing completes, print a label with:

- Batch number and material name

- Dispensed quantity and lot number

- Date, time, and operator

- Barcode for downstream verification

Labels are part of the batch record. When someone scans the container later in the process, the system verifies it's the right material for the right batch at the right step. The label isn't just identification—it's the bridge between dispensing and downstream processing.

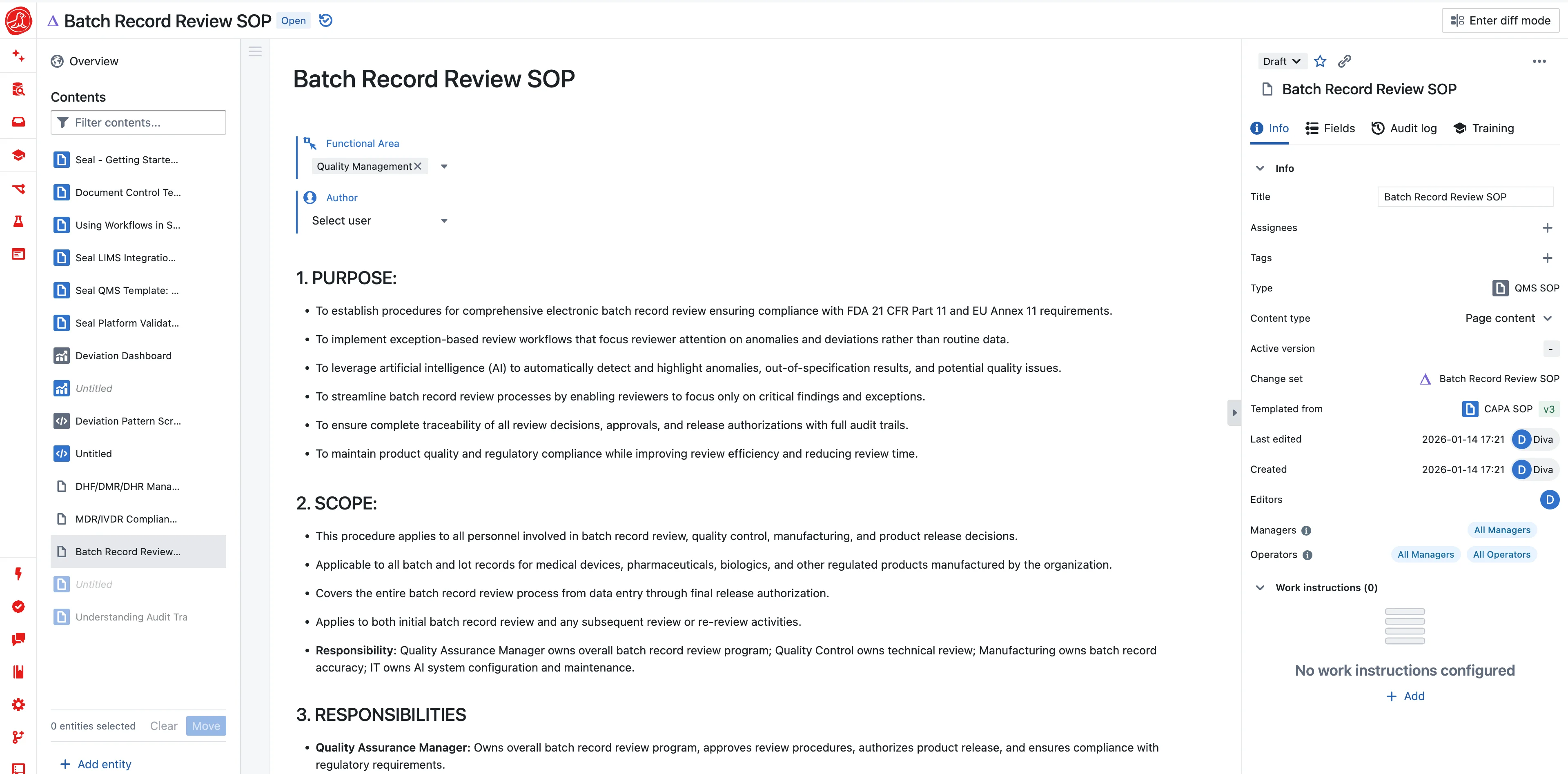

The integration advantage

Because weighing and dispensing live on the same platform as your batch records, inventory, and quality system, everything connects automatically. A deviation during dispensing opens in the QMS with full context attached. Equipment calibration status is checked before the balance can be used. Operator training is verified before they can execute the step.

This isn't three systems with interfaces. It's one system where dispensing is a native capability. The data flows because it was never separate to begin with.

Capabilities