Equipment & Assets

Calibrate. Maintain. Qualify.

Track calibration, maintenance, and usage. Block out-of-spec equipment automatically.

Equipment failures aren't random. They're predictable.

That HPLC that failed mid-batch? It showed warning signs for weeks. That centrifuge that contaminated samples? Maintenance was overdue by months. That bioreactor running out of spec? The last calibration was never logged. You can see these failures coming—if your systems are paying attention. The problem is they're not. Your equipment data is scattered across five systems, three spreadsheets, and a binder in the corner of Lab A. By the time anyone notices a problem, the batch is already ruined.

Walk through your facility and trace a single instrument's data. Calibration schedules live in an Excel spreadsheet that Katie maintains—she's on vacation this week. Usage logs sit in paper binders that operators sign when they remember. Maintenance records exist in the CMMS, which doesn't talk to anything else. Service contracts are PDFs buried somewhere in SharePoint. Deviation history lives in the QMS, but you have to search by equipment ID manually. And the current calibration status? That's a sticker on the side of the instrument. Whether it's accurate is anyone's guess.

Here's how most organizations "manage" calibration: Metrology calibrates the equipment and sticks a label on it reading "Calibrated: 03/15/24, Due: 06/15/24." Operators glance at the sticker before use. If it looks current, they proceed. What could go wrong? Everything. The sticker fades or falls off. The operator doesn't check it because they're in a hurry. The calibration actually failed, but nobody updated the sticker. The sticker is correct, but the spreadsheet shows something different. The due date passed three days ago, but nobody noticed because nobody checks the spreadsheet daily. Every one of these scenarios has caused real compliance events. Some have caused product recalls. The sticker is not a control. It's a hope.

Some organizations upgrade from stickers to electronic warnings. The MES shows a popup: "Equipment calibration expired. Do you want to continue?" This feels like progress. It isn't. The data is clear: operators click "Continue" 87% of the time. They're busy. They're under pressure to complete the batch. The popup is annoying. They assume someone else is tracking it. A warning is not a control. It's a suggestion that operators routinely ignore. Seal doesn't warn. Seal blocks. When equipment is out of calibration, it cannot be selected for GMP work. There's no "Continue" button. There's no override. The equipment simply doesn't appear as an option until calibration is current. This isn't heavy-handed—it's the only approach that actually works.

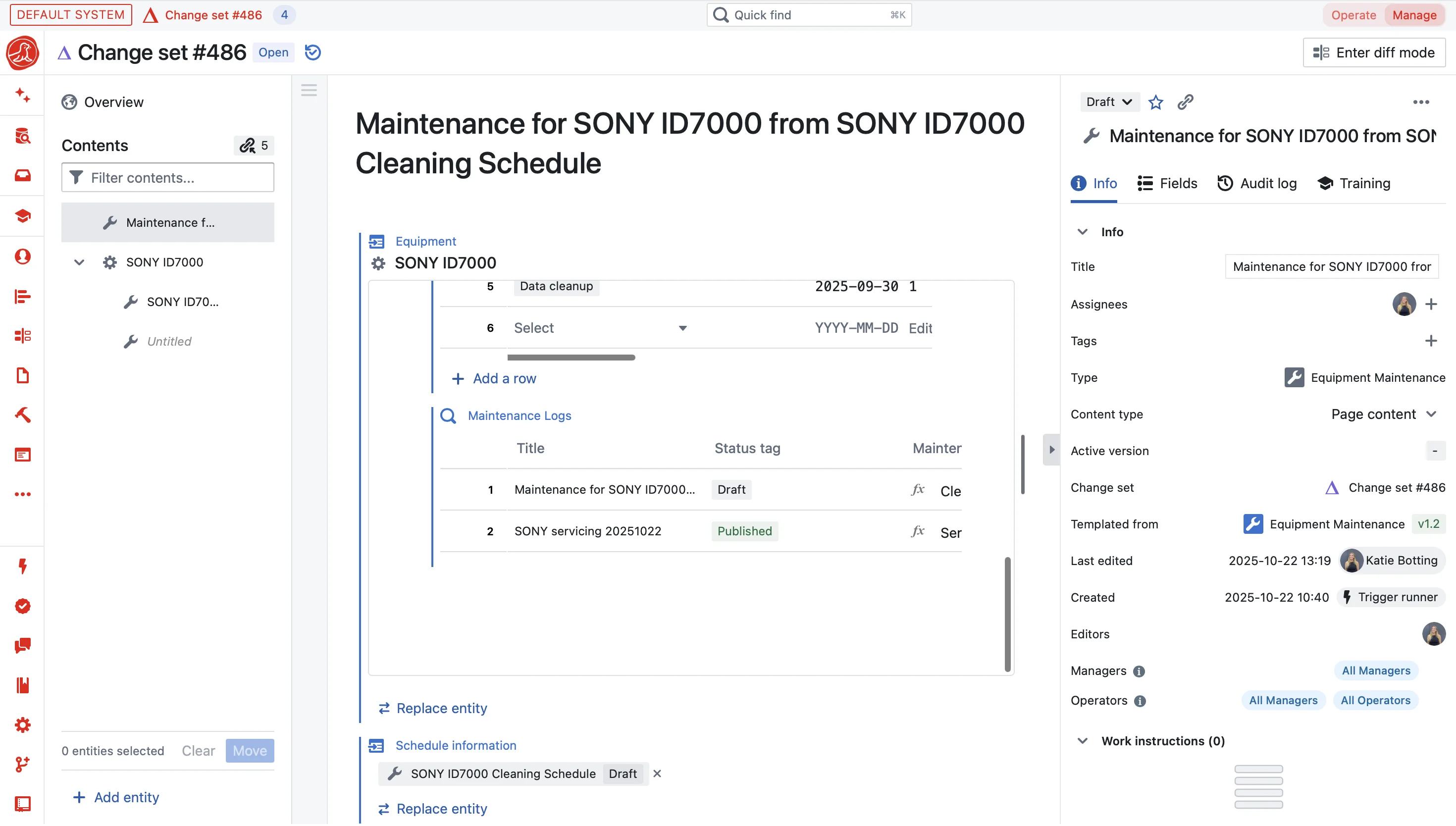

Equipment states and automatic tracking

Equipment isn't binary. It moves through states, and those states determine what you can do with it. Every piece of equipment in Seal exists in one of four states. Available means calibration is current, cleaning is verified, and operators can select it for batches and tests. In Use means it's currently assigned to a batch or sample—the system tracks who's using it, for what purpose, and when they started, preventing other operators from selecting it. Cleaning Required means usage is complete but cleaning hasn't been verified yet, so it can't be used again until that's logged. Out of Service means calibration expired, maintenance is overdue, or someone manually took it offline—equipment in this state cannot be selected for any GMP work, period. The key insight is that state transitions are automatic and enforced. When calibration expires, the equipment moves to Out of Service without anyone lifting a finger. When cleaning is verified, it moves to Available automatically. Operators don't manage states. The system does.

In most organizations, usage logging is a manual process. Operators sign a paper log or fill out a spreadsheet. They forget. They approximate. They backfill at the end of the day. In Seal, usage is logged automatically because equipment selection is part of the workflow. When an operator starts a batch step, the system prompts them to select equipment. They scan a barcode or choose from a list—but only Available equipment appears. The system immediately logs the equipment ID, operator, timestamp, and batch step, linking the usage to both the equipment record and the batch record. When the step completes, the system prompts the operator to release the equipment. They confirm, and the system logs the end timestamp, calculates total usage time, and transitions the equipment to Cleaning Required if that's how you've configured it. No paper logs. No manual data entry. No "I forgot to log that run from yesterday." The equipment record becomes a complete history: every batch it touched, every test it ran, every operator who used it, every cleaning event, total hours of use, and usage trends over time.

Calibration and maintenance

Calibration in Seal isn't a spreadsheet. It's a managed workflow with enforced schedules and automatic blocking. Each equipment type has a defined calibration schedule specifying how often calibration occurs, which procedure to follow, who can perform it, and what data to capture. When equipment approaches its due date, the system sends reminders to Metrology at configurable intervals—30 days, 14 days, 7 days. It creates a calibration work order that can be assigned to specific personnel. If the due date passes without completion, the equipment is automatically blocked. Metrologists execute calibrations within Seal by opening the work order, following the procedure, and recording measurements. The system compares results to specifications. If calibration passes, the equipment returns to Available and the next due date is calculated. If it fails, the equipment remains Out of Service and triggers a CAPA workflow. Calibration certificates generate automatically with all data, signatures, and traceability. Some organizations need short grace periods for operational flexibility, and Seal supports this—equipment remains usable during the grace period with a warning, but after expiration comes the hard block.

Equipment needs more than calibration. It needs preventive maintenance, corrective repairs, and vendor service. Preventive maintenance schedules can be time-based (every six months), usage-based (every 500 hours), or hybrid (whichever comes first). The system tracks both dimensions automatically and triggers work orders accordingly. When PM is due, the system creates a work order with the procedure and parts list, assigns it to the maintenance team or an external vendor, and sends reminders as the due date approaches. Technicians complete work orders by logging the tasks performed, parts used (linked to inventory), time spent, and any observations, with electronic signatures for verification. For equipment serviced by vendors—say, annual Agilent PM on your HPLCs—Seal tracks service contracts with expiration dates, logs vendor visits with technician names, attaches service reports, links to purchase orders and invoices, and monitors contract renewal dates. Everything in one place, linked to the equipment record.

Auditors ask the same question every time: "Show me the complete history for this instrument." Before Seal, answering this question is an exercise in archaeology—find the calibration spreadsheet (15 minutes), locate the usage logbook (10 minutes), email maintenance for a CMMS export (20 minutes if you're lucky), search the QMS for deviations (15 minutes), find the service contract in SharePoint (10 minutes), compile everything into a Word document (20 minutes). That's 90 minutes per equipment request, and the auditor will ask about three to five instruments. After Seal, you search for the equipment ID, click on the record, and show the auditor the screen. Five seconds. The equipment record displays current status and location, complete calibration history, all maintenance events, every batch and test it was used in, every deviation it was involved in, service contracts and vendor visits, and training status of personnel who use it. Every entry is timestamped, attributed, and linked to source records. The auditor can drill down into any event. You don't explain or justify—you show.

Integration with operations and AI

Equipment management doesn't exist in isolation. It connects to everything else in your operation. When a batch record calls for specific equipment, only calibrated, available equipment appears in the selection list. The selection is logged automatically. If equipment goes out of service mid-batch, the system alerts the operator immediately. When a test method specifies equipment, the system verifies that equipment is qualified for the method before allowing the test to proceed. It captures the equipment ID with each result. If results come back out of spec, the equipment is flagged for investigation. When a deviation is opened, the system suggests equipment that might be involved based on timestamps and location, links equipment to the deviation record automatically, and shows equipment history right on the deviation form for context. When equipment is involved in a recall or investigation, the system identifies all batches that used it and generates an impact assessment automatically. Equipment often requires specific training to operate—you can define required training per equipment or equipment type, and the system verifies operator training before allowing equipment selection. If training expires, the operator is blocked from using that equipment until they're recertified.

Seal's equipment module can be deployed independently or as part of the integrated platform. For standalone deployment, you import your equipment list via CSV or API, define calibration and maintenance schedules, configure status rules and blocking behavior, and deploy to your teams. You can integrate with existing systems via API—pulling calibration records from your metrology system, pushing equipment status to your MES, syncing with your CMMS for maintenance. When equipment is part of the full Seal platform, everything connects automatically: equipment selection in MES batch records, equipment verification in LIMS tests, automatic deviation linking in QMS, training requirements enforced at equipment selection. No integration project required. You don't have to migrate ten years of history on day one. Import your current equipment list and status in week one. Configure calibration schedules going forward in week two. Begin logging new usage and maintenance in week three. Go live with enforcement in week four.

Setting up equipment shouldn't mean re-typing specifications from manufacturer manuals. Drop your equipment documentation—user manuals, datasheets, calibration certificates, service records—and AI extracts what matters. AI identifies equipment specifications, recommended calibration intervals, operating parameters, and maintenance requirements directly from manufacturer documentation. A 200-page HPLC manual becomes a structured equipment record with calibration schedule, PM tasks, and operating limits—in minutes, not hours. Based on equipment type, manufacturer recommendations, and regulatory requirements, AI suggests appropriate calibration intervals and tolerance limits. You review and adjust, but you're not starting from a blank spreadsheet. Have years of calibration certificates in PDFs? AI extracts calibration dates, results, and technician information into structured records. Your equipment history imports with traceability intact. The pattern is consistent: AI extracts, you review the changeset, approved data enters the system.

Equipment compliance failures are expensive. A single deviation costs $5,000 to $15,000 in investigation, documentation, and review. A batch hold costs $50,000 to $500,000 or more depending on product value. A recall can cost anywhere from $1 million to $100 million. A 483 observation runs $100,000 or more in remediation, consultant fees, and management attention. Organizations with enforced equipment management see 70-90% reduction in calibration-related deviations, near-zero equipment selection errors, and 80% or greater reduction in audit prep time. Fewer holds, faster releases. The investment pays for itself with the first avoided deviation.

Capabilities