Downstream Development

Purify. Optimize. Scale.

Purification development in an execution system. Chromatography, filtration, formulation—structured capture that survives tech transfer.

The purification process that couldn't transfer.

The downstream team optimized for eighteen months. They knew the chromatography: resin selection, loading capacity, elution profiles. They understood the filtration: flux decay patterns, diafiltration requirements, membrane fouling. The process achieved 70% overall yield with excellent purity.

Tech transfer came. The batch records were written. Manufacturing ran the first batches. Yields dropped to 50%. Same steps, same parameters—different results. The knowledge that made the process work was in notebooks, in experience, in "we always do it this way" tribal understanding. The batch record captured what to do. It didn't capture why.

Purification in an execution system

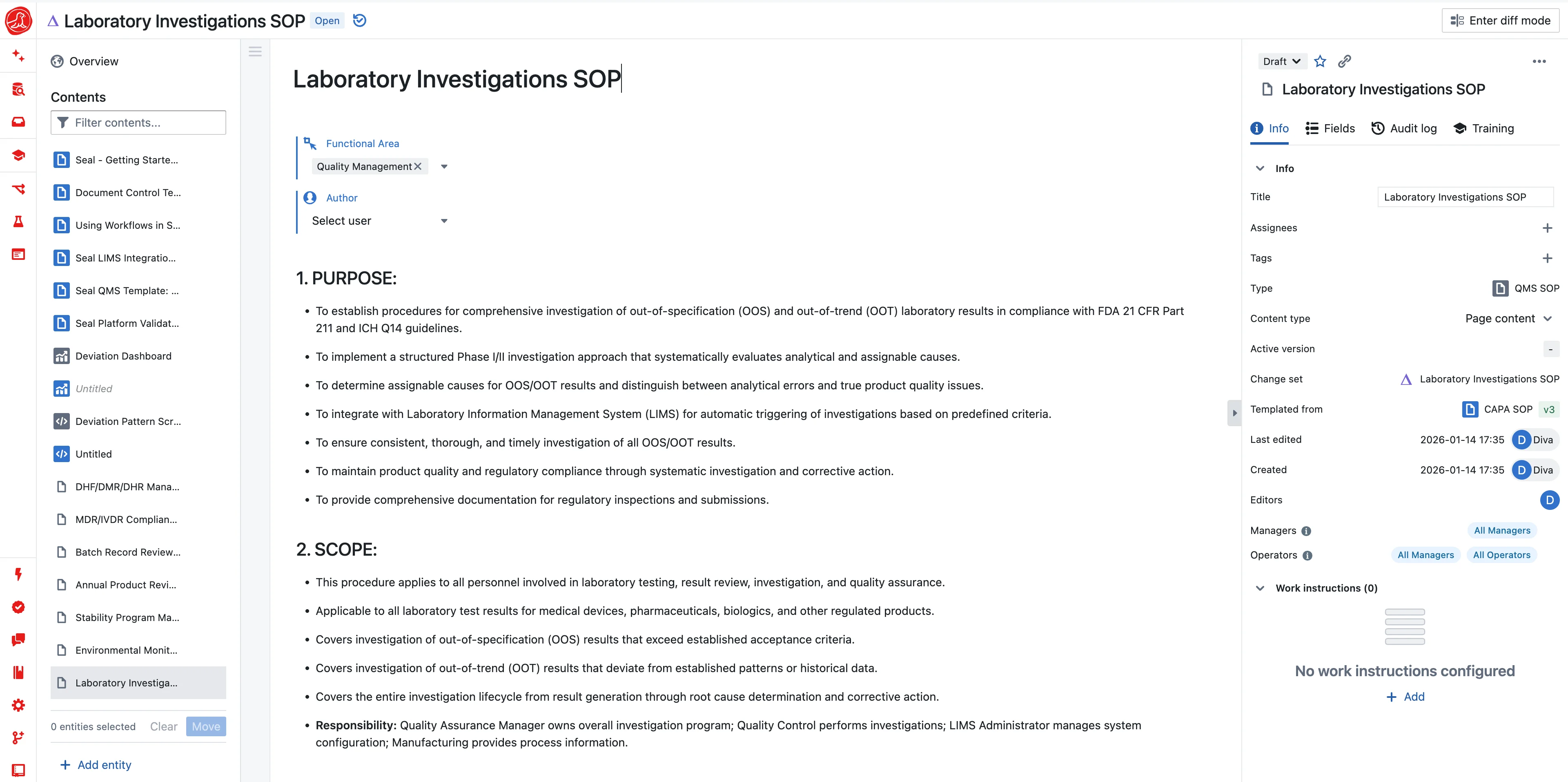

Most downstream development happens in documentation systems. Scientists run experiments and write reports, but the context—why those buffer conditions, how the loading was optimized, what happens when conductivity drifts—lives outside the documentation. Seal is an execution system for downstream development where scientists define purification steps as structured workflows. As steps execute, parameters capture automatically, buffer preparations link to the steps that use them, and column history accumulates with every run. The process isn't documented after the fact—it's recorded as it executes.

Chromatography steps have dozens of parameters: flow rates, buffer compositions, gradient profiles, loading density, residence time. Optimizing these takes months, and the optimization path is often lost by the time the process locks. Every run in Seal records the parameters used and results achieved, so when a parameter changes the change is tracked, and when results improve or degrade the data shows why. Buffers drive separation—a 0.1 pH unit shift can change selectivity, a conductivity variation can affect binding. Seal versions buffer formulations and links preparations to runs, so when results vary you can see exactly what buffer was used: not "equilibration buffer" but "EQ Buffer v3.2, Lot 2024-0156, pH 7.41, conductivity 15.2 mS/cm."

Consumables, intermediates, and lifecycle tracking

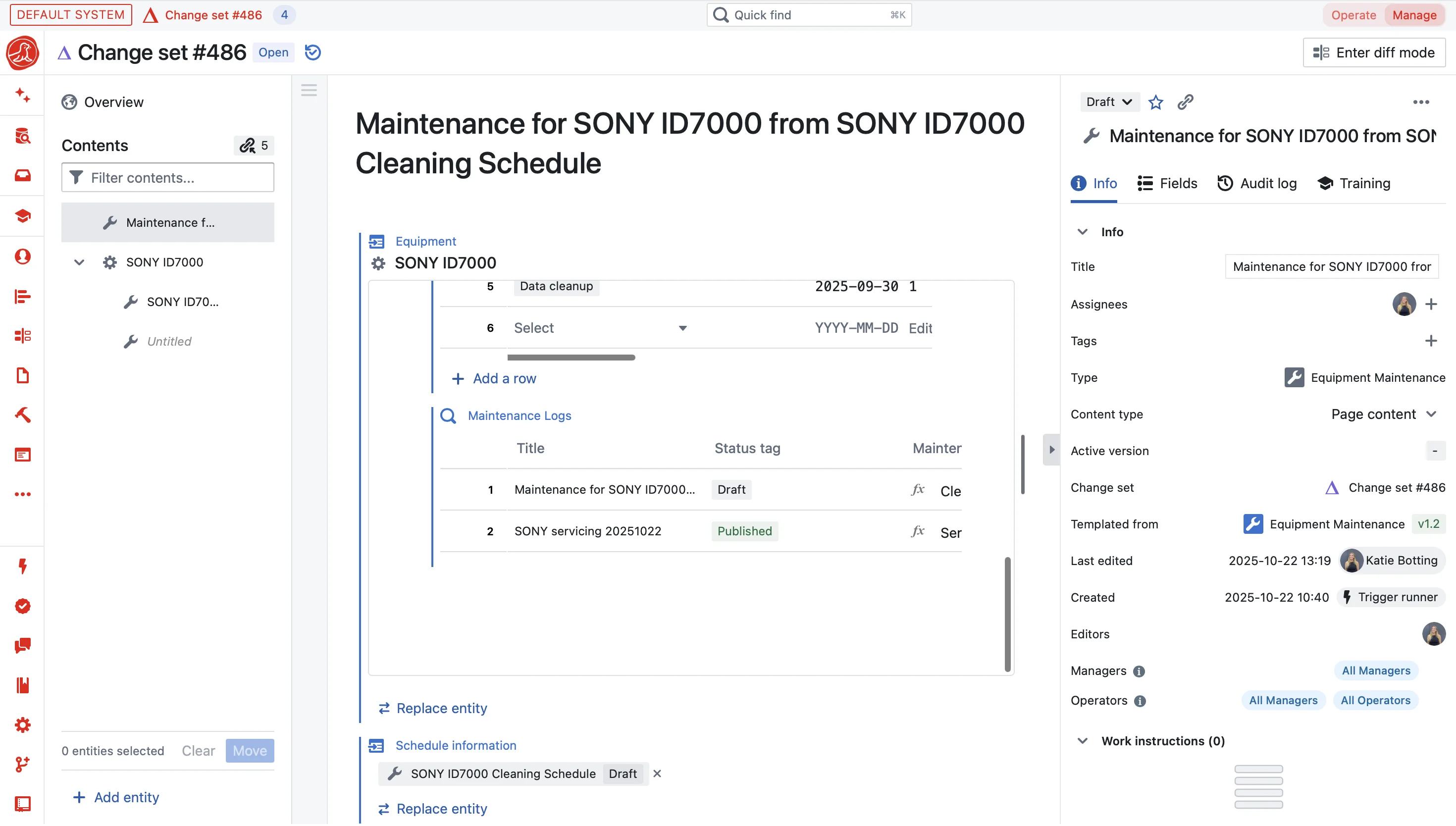

Columns are expensive assets with finite lifetimes. Resin degrades, capacity drops. Knowing when to retire a column—and proving that decision to regulators—requires lifecycle data. Seal tracks column lifecycle as integral to purification execution: cycles, volumes processed, CIP events, requalification results all accumulate with every run. Capacity trends emerge from data and retirement decisions are supported by evidence.

Filtration steps seem simple—push liquid through a membrane—but flux decay, fouling, and membrane lifetime make filtration development complex. Seal structures filtration as first-class purification steps with filter specifications linked to runs, flux data captured throughout operation, and diafiltration volumes and concentration targets stored as structured data. Resin and membrane replacement decisions are supported by actual performance degradation patterns, not just cycle limits.

Purification creates intermediates: the eluate pool from chromatography, the retentate from UF/DF, the bulk drug substance before formulation. Seal tracks these as first-class entities with defined attributes, measured results, and timestamps. Hold times calculate automatically, and when an intermediate approaches its limit the system knows. In-line and at-line PAT measurements link directly to process execution—UV traces, conductivity profiles, pressure differentials all become part of the process record, not a separate data stream.

From development to manufacturing

Viral clearance studies are critical and expensive. The data must link clearly to the process being validated, and when the process changes, impact must be assessed. Seal links viral clearance to process definitions—the low pH inactivation step that was validated links to the purification workflow, the nanofiltration parameters that achieved log reduction link to the filtration definition. When process changes are proposed, impact on clearance claims is visible because the claims trace to specific parameters.

The purification process at bench scale doesn't automatically work at manufacturing scale. Column diameters change, flow rates scale differently, hold times matter more. Seal captures scale relationships as structured data—when you run at multiple scales, parameters and results align by step, and scale correlations build from actual data rather than generic guidelines. Development considers manufacturing constraints from the start: equipment sizes, hold time limits, cleaning requirements are all visible during development rather than discovered at tech transfer.

Downstream doesn't exist in isolation. What comes from the bioreactor affects purification—titer, cell viability, harvest clarity all influence yield and quality. Seal connects downstream to upstream so the harvest that feeds purification links to the bioreactor run that produced it. Formulation connects too: the bulk drug substance from downstream links to formulation runs, and formulation parameters link to stability outcomes. When you optimize end-to-end, you're working with connected data from cell culture through final product.

AI and legacy data

Downstream processes are complex. Chromatography separations depend on dozens of parameters, yield losses accumulate across steps, and finding the relationships requires analyzing patterns across many runs. Seal applies AI to downstream data—natural language queries let you ask "what's the average step yield for Protein A chromatography when loading above 30 g/L?" and get answers from your data. Pattern recognition identifies relationships between upstream conditions and downstream performance.

Your development archive contains valuable information—purification runs from years ago, optimization studies in reports, resin performance data in spreadsheets. This knowledge cost millions to generate but is locked in formats that don't connect to today's work. Seal can import and structure historic data through AI-assisted extraction, so when you develop a new process you're building on everything you've learned rather than starting over.

Capabilities