Maintenance Management

Maintain. Calibrate. Optimize.

Temperature warnings for two weeks—noted in the logbook, never escalated. PM overdue by a month. Friday the bioreactor failed. Monday was harvest. $2.3 million batch lost.

The bioreactor that failed on a Friday.

Harvest was scheduled for Monday. Friday afternoon, the temperature control failed. No spare parts on hand. The supplier couldn't ship until Tuesday. The cells—a patient's own cells, the only batch possible for that patient—died over the weekend. A $2.3 million loss on paper. An immeasurable loss for the patient who ran out of options.

Post-mortem revealed the temperature controller had been showing intermittent warnings for two weeks. They were noted in the logbook but never escalated. Preventive maintenance was overdue by a month—the PM schedule lived in a spreadsheet that hadn't been updated. The warning signs were there. The system to act on them wasn't.

This is the reality of equipment maintenance in life sciences. Every bioreactor, every filler, every autoclave, every analytical instrument sits between your process and your patients. When equipment fails, batches fail. When batches fail, patients wait—or don't get treated at all.

Reactive maintenance is a tax on production. Preventive maintenance is an investment in reliability. But investment only pays off when maintenance actually happens.

The gap between schedule and execution

Every facility has preventive maintenance schedules. Annual pump rebuilds. Quarterly calibrations. Monthly filter changes. The schedules exist because they're required—by SOPs, by equipment manufacturers, by regulators who will ask to see them.

But schedules don't maintain equipment. Execution does.

PM schedules exist on paper or in spreadsheets. Equipment runs; maintenance slides. "We'll get to it next week" becomes next month becomes after the next campaign becomes after the failure. The spreadsheet shows the PM is overdue, but the spreadsheet is in someone's email. The operator doesn't know. The supervisor doesn't know. Production keeps running until something breaks.

The PM that could have prevented Friday's failure was scheduled for three weeks ago. It's still scheduled. It just never happened.

Preventive maintenance that actually happens

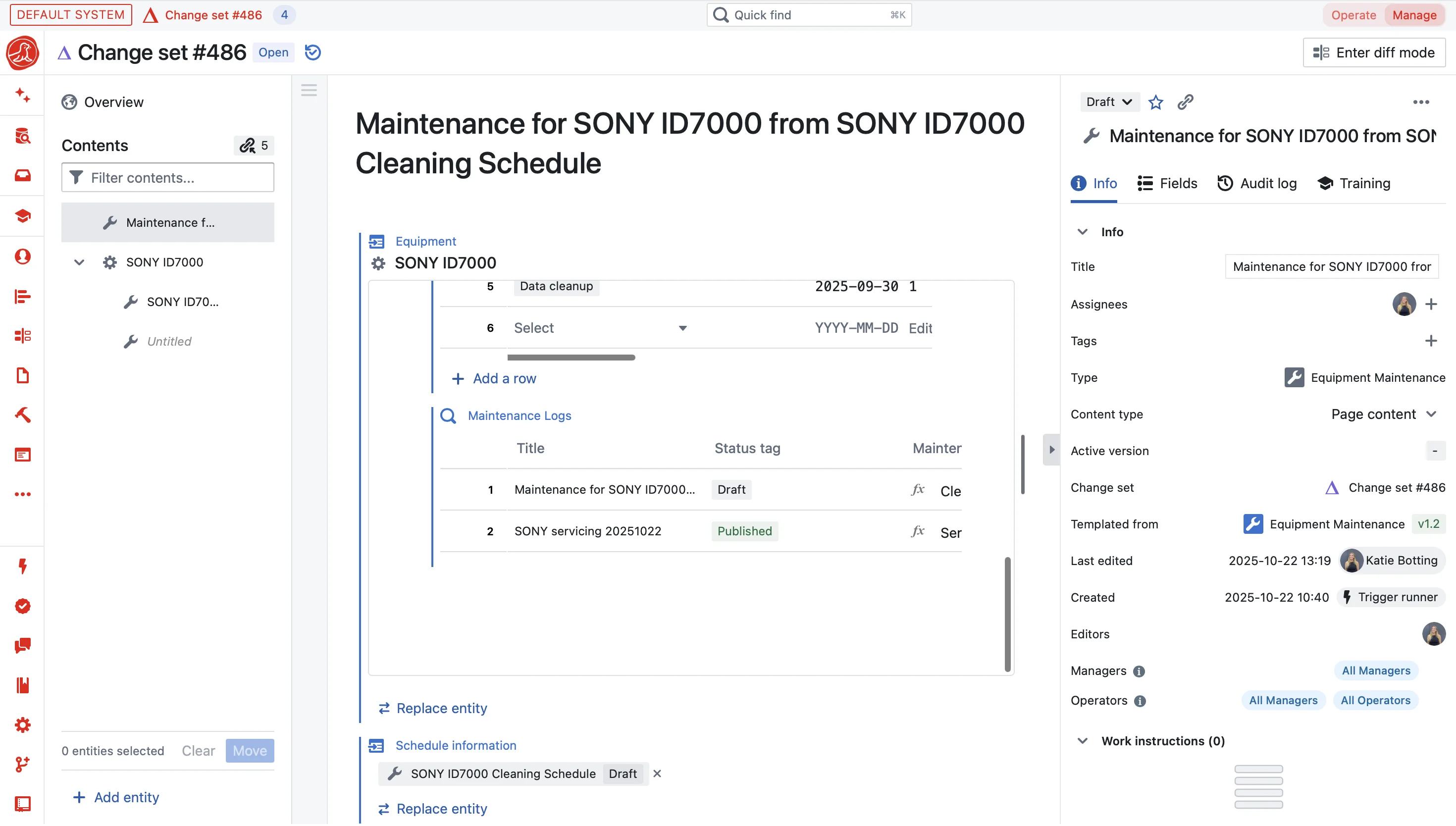

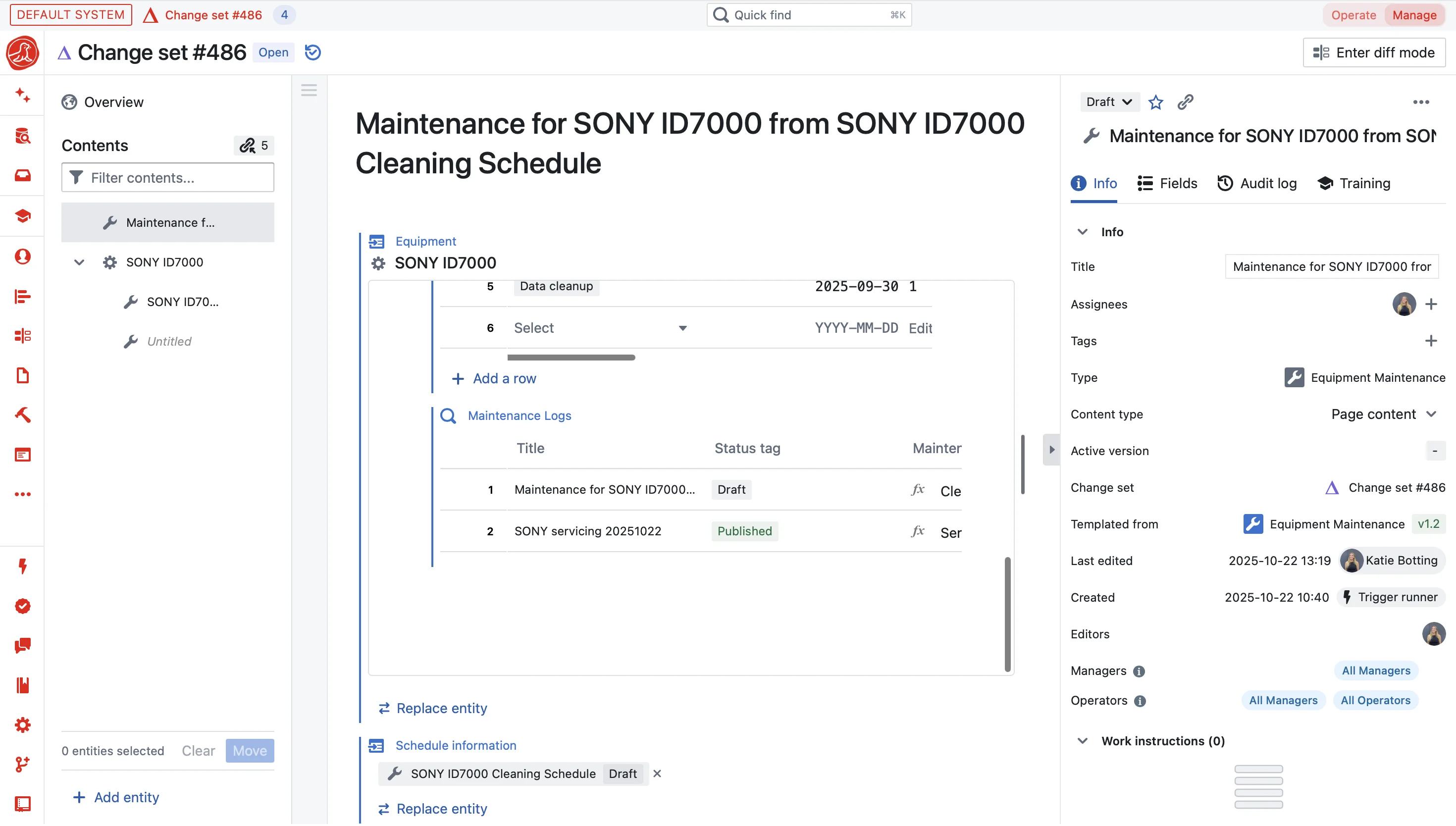

Seal makes PM schedules operationally visible. Dashboard shows what's due today, this week, overdue. Maintenance work orders generate automatically on schedule—not when someone remembers to check the spreadsheet, but on the date the PM is due. If a PM slips, it's visible to production, to management, to everyone who needs to know. Not hidden in someone's email. Escalated.

When maintenance and production share visibility, maintenance happens. When the production planner sees "Reactor 3 PM due in 5 days" while scheduling the next campaign, they schedule around it instead of through it. When the maintenance supervisor sees three overdue PMs on the dashboard every morning, they can't pretend they don't exist.

The discipline isn't heroic individual effort. It's system design.

Work orders from request through completion

Something needs fixing. An operator notices a strange vibration. An alarm fires. A quality deviation implicates equipment. A scheduled PM comes due. How does observation become action?

Seal captures maintenance requests from any source—operator observation, alarm system, quality event, scheduled PM, predictive monitoring. Each request becomes a work order with categorization, priority, assignment. The request doesn't disappear into email. It becomes a tracked object with a lifecycle.

Technicians see their queue. Supervisors see status across all work. Completion captures what was done, what parts were used, how long it took, what was found. The documentation that GMP requires—who did what, when, to what equipment, with what results—generates as work happens, not as an afterthought.

No work disappears into the void. No "I thought you were handling that." No deviation investigation that discovers the maintenance logbook was never filled in.

Spare parts that are there when you need them

The bioreactor failed on Friday because parts weren't on hand. Parts weren't on hand because nobody tracked what was needed. The temperature controller is a $3,000 part with a 5-day lead time. Nobody thought to keep a spare until the day they needed one.

Every piece of critical equipment has critical spare parts. Seals, sensors, controllers, drives, filters—components that fail and need replacement. Without spares, equipment stays down until procurement and shipping happen. Days or weeks of lost production because a $500 part wasn't in stock.

Seal links spare parts to equipment. You define what parts each piece of equipment needs. Critical equipment has minimum stock levels for critical parts—fall below minimum and reorder triggers automatically. When technicians use parts, they log consumption; inventory decrements. Lead times are known, so long-lead parts reorder earlier. When a part with a 6-week lead time hits its reorder point, you know 6 weeks before you'll need it—not the day you need it.

The part you need is in the stockroom because the system knew you'd need it before you did.

Calibration tracking with GMP rigor

Calibration in GMP isn't optional. Instruments must be calibrated. Calibration must be current. Out-of-calibration conditions must trigger impact assessment—what measurements were affected? What batches? What release decisions?

The calibration sticker says "Cal Due 6/15." Today is 7/12. The QC analyst uses the balance anyway—they didn't check. Three weeks of analytical results are now suspect. The batch records that used those results are under investigation. Release is on hold.

Seal tracks calibration status for every calibrated instrument. Due dates are visible. Overdue calibrations escalate—they can't be ignored because the system surfaces them. Production can't use equipment that isn't calibrated; batch records check calibration status before allowing use. When calibration occurs, results record with certificates attached. Out-of-tolerance conditions flag for investigation: here are the batches, here are the results, here's the assessment workflow.

The out-of-calibration balance can't be used because the system won't let it be used. That's not bureaucracy. That's data integrity protection.

Reliability metrics that drive improvement

How often does this equipment fail? What's the mean time between failures? What's the mean time to repair? Which equipment is most problematic? Which failure modes recur?

Without data, these questions get answered by impression and memory. "The filler is always breaking down." Is it? Or is it just memorable when it does? Maintenance budgets, capital replacement decisions, reliability improvement initiatives—all based on feelings rather than facts.

Seal calculates reliability metrics from work order data. MTBF, MTTR, availability—by equipment, equipment class, production area. Not estimates, not impressions—calculations from actual work order history. Trending shows if reliability is improving or degrading. Pareto analysis shows which equipment and which failure modes drive the most downtime.

When you can see reliability, you can improve it. When you can prove reliability, capital requests have data behind them. "Reactor 3 has failed 7 times this year with a total cost of $4.2 million in lost batches. Replacement cost is $1.5 million." The business case writes itself.

Integration with production

Equipment downtime affects production. Production schedules affect maintenance windows. In most organizations, these are separate systems with manual coordination—production planning in one tool, maintenance scheduling in another, coordination by email and meetings.

Seal integrates maintenance with production scheduling. Maintenance windows schedule around production runs, not through them. When unplanned downtime occurs, production scheduling sees it immediately—not after someone sends an email. Equipment status is visible to operations: don't schedule that reactor, it's in maintenance. Don't plan that campaign, the autoclave PM is due mid-week.

When maintenance completes and equipment returns to service, production sees it. No "is the reactor available?" phone calls. No spreadsheet that's out of date by the time it's updated. Current state, visible to everyone who needs it.

The equipment that keeps patients safe

Behind every maintenance decision is a patient. The bioreactor that failed on Friday wasn't just expensive—it held living cells that can't be replaced. The out-of-calibration balance didn't just produce suspect data—it produced suspect results that gate product release. The overdue PM didn't just increase failure risk—it increased the risk that a critical therapy won't be available when a patient needs it.

Equipment maintenance in life sciences isn't like equipment maintenance in other industries. In manufacturing widgets, equipment failure means production loss and financial impact. In manufacturing medicines, equipment failure can mean a patient doesn't get treated.

The PM that happened on schedule, the spare part that was in stock, the calibration that stayed current, the work order that didn't fall through the cracks—these aren't operational conveniences. They're links in the chain between your process and your patients.

Seal doesn't make maintenance heroic. It makes maintenance systematic. And systematic maintenance is how you ensure that the equipment patients depend on is there when they need it.

Capabilities